Port of Bandon Marina

Bandon, Oregon

West Coast Contractors, Lee Composites, Bellingham Marine

The town of Bandon, Oregon was founded in the mid-1800s at the mouth of the Coquille River on a scenic part of the state’s southwest coast. By the time the U.S Army Corps of Engineers built a jetty at the Port of Bandon in 1884, the town was a center for the export of salmon, cranberries and salmon.

More recently, Bandon has become better known for sportfishing and for its highly rated Bandon Dunes golf resort. As recreational boating supplanted commercial salmon fishing, a marina in the Port of Bandon was first constructed in 1984 by the Donald W. Thompson Construction Company. Forty years later, the marina has exceeded its designed life with aging piling and docks in need of repair or replacement. Had been seeking funding for the project for a few years, working hard to land a number of grants designed to provide economic development and vitality in the area.

The Port awarded a design-build contract to West Coast Contractors (WCC). Work began in the fall of 2023 and is expected to be completed by the summer of 2024.

The design work for the project was performed throughout the summer of 2023 by KPFF from Seattle. Existing dock facilities were removed in October and piling pulled using WCC’s Kobelco CK1100 crawler crane and an APE 200 vibratory hammer, working from a modular barge.

Dredging of the marina and nearby boat ramp needed to be completed prior to reconstruction could begin. Over 36,000 cubic yards of material were removed by the dredging subcontractor utilizing a suction dredge. Bathymetric surveys were done to assure correct levels were achieved. Due to salmon runs, the in-water work proceeded throughout the winter in rain, winds, currents and tides.

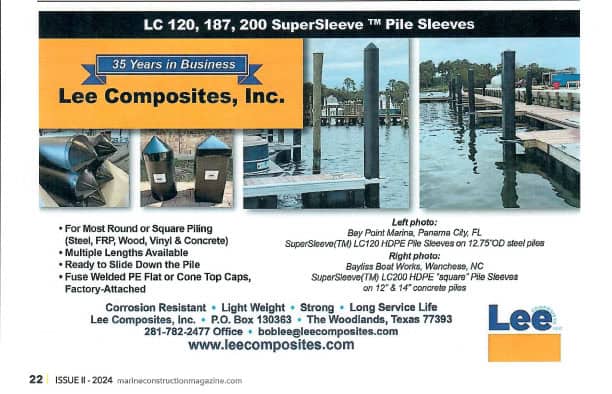

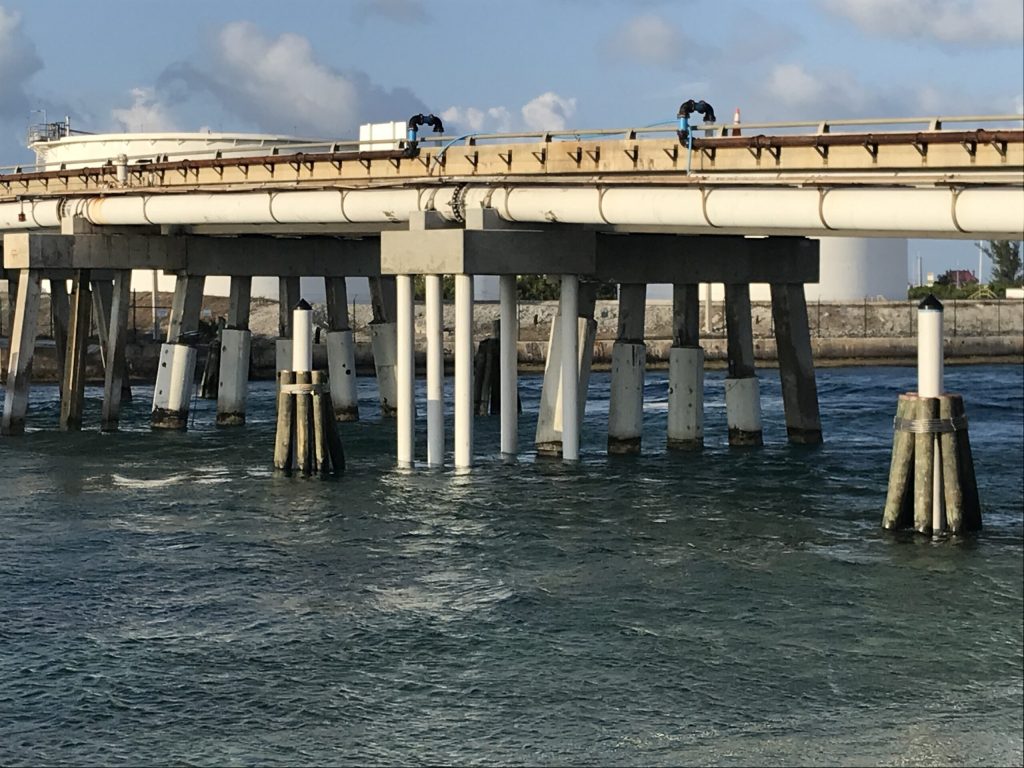

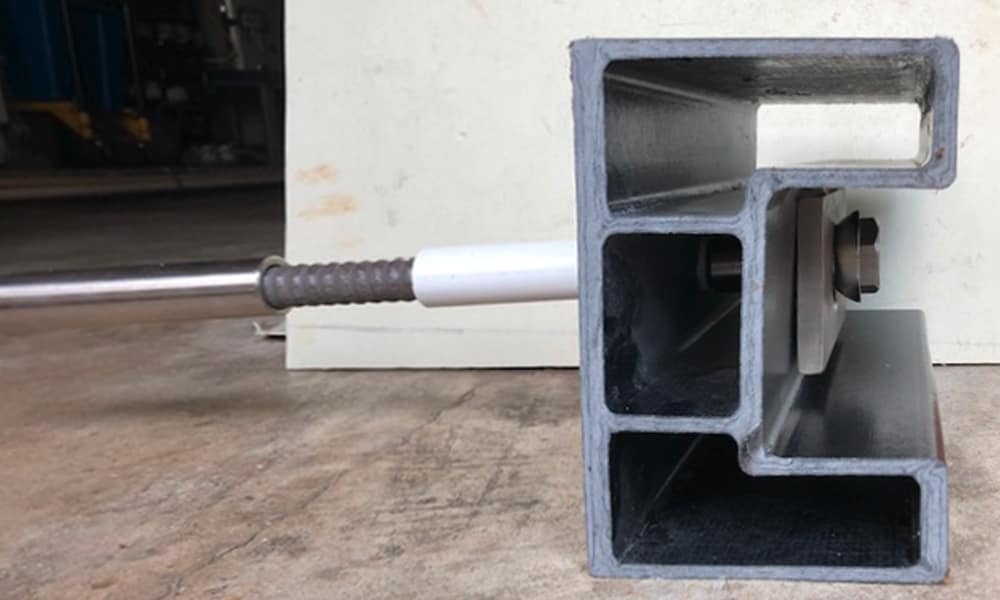

With the dredging accomplished, WCC began constructing the new facilities. The new marina consists of 80 slips on five docks. Forty-eight steel piles—each measuring 60 feet high by 16 inches wide—were driven into the rock, 13 to 30 feet below mudline. SuperSleeveTM HDPE sleeves manufactured by Lee Composites were placed over each pile to prevent corrosion and chafe.

The harsh conditions along Oregon’s coastline present challenges for marine facilities. One factor is a large tidal swing: On March 22, 2024, the swing from low tide to high tide at the mouth of the Coquille River was six feet. And although the marina at the Port of Bandon is a certified “Oregon Clean Marina,” chemicals in the Coquille from the lumber industry remain a persistent threat.

A more constant condition is wind. According to WeatherSpark, the average hourly wind velocity at the Port of Bandon from November to April is 8.3 miles per hour, and 9.5 in December. That wind creates constant river chop, and in turn, a lot of chafe on pilings.

The use of HDPE pile sleeves eliminated the need to coat steel piles with anti-corrosion chemicals. The Lee Composites sleeves are custom manufactured— 37 feet long, 16.5 inches in diameter and sleeve thickness of .187 inches for the Bandon job—and slip over the piles and into the mudline, isolating the pile from the salt water.

“These pile sleeves are a game changer for marine facilities like Bandon,” said WCC’s Senior Project Manager Chad Walker. “This will add years to the life of the piling.”

Dock sections were manufactured by Bellingham Marine and installation was sequenced with the pile driving schedule. Once in the water, the sections were attached together and utilities were run. Divers were used as needed on the project although water visibility is minimal during Oregon’s wet winters. “It was like construction by Braille,” stated WCC Superintendent Don Thompson, who long after the marina was first built is involved in its reconstruction. “The divers couldn’t see more than an inch or two in front of their faces.”

Much has changed at the Port of Bandon, both since its early history and since the marina’s original construction. The current infrastructure, should serve marine operations at this scenic location long into the future.