SuperSleeve™ HDPE Pile Sleeves Stand Strong at Snook Bight Marina

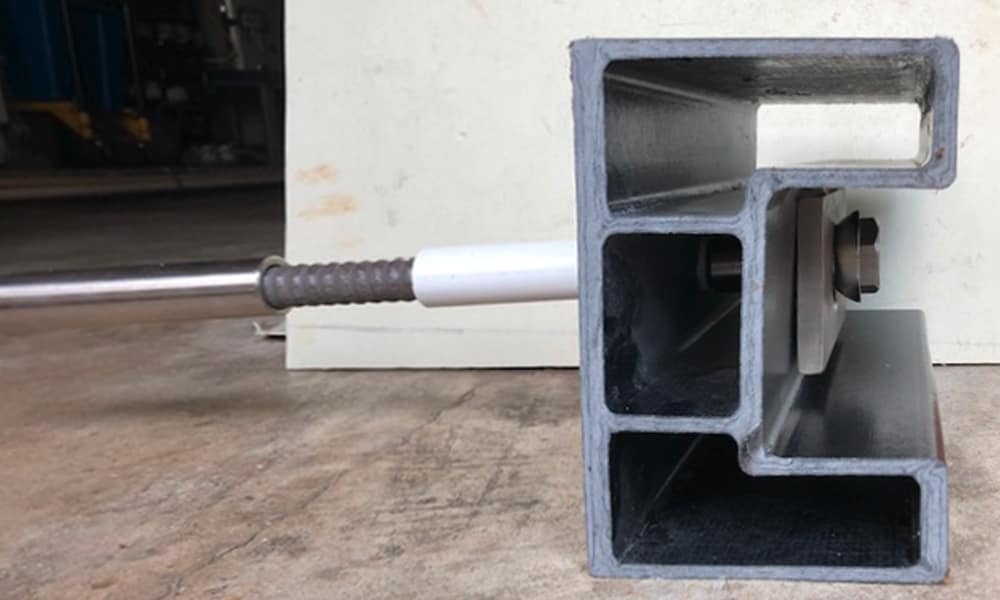

Last week, we revisited Snook Bight Marina in Fort Myers Beach, FL, to check on the performance of our SuperSleeve™ HDPE Pile Sleeves. Installed by Gorman Marine Construction on 16” OD steel piles with Golden Boat Docks, these sleeves were put to the test after enduring two hurricanes. The result? Zero damage—proof of their durability and reliability.

Our SuperSleeve™ HDPE Pile Sleeves LC200 (.200″ thick) are designed to fit steel, fiberglass, or concrete piles measuring 12” or greater in diameter. Manufactured in Houston, TX, the sleeves are pre-fabricated, easy to install, and equipped with fuse-welded caps to create a seamless, rust-free system.

From their robust design to their proven resilience, our pile sleeves are engineered to protect your investments, no matter the conditions.